Wastewater Treatment

Wastewater from more than 10,000 homes and businesses reaches the plant through 73 miles of underground pipeline. Where the water cannot flow by gravity, it is pumped by four strategically placed pump stations. An average of 1 million gallons per day reach the treatment plant.

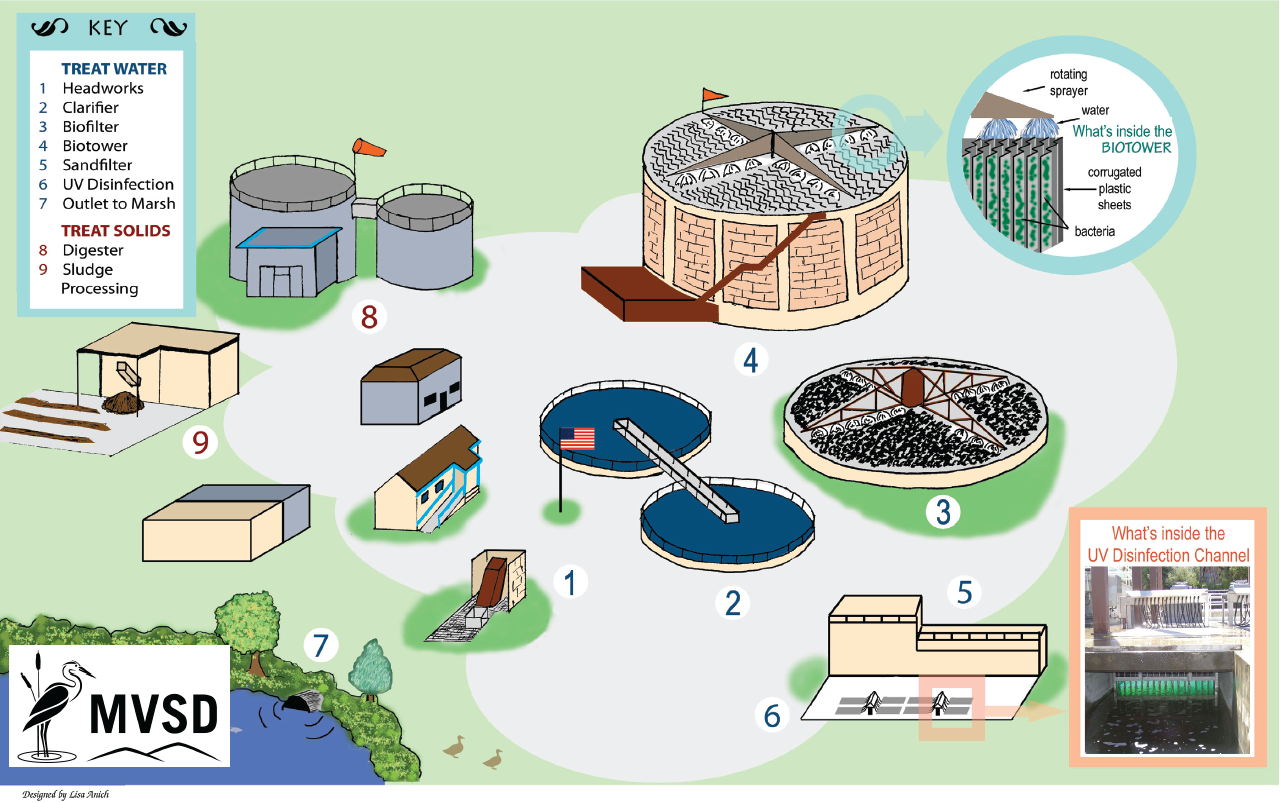

Use the guide below to go through the processes:

- Headworks: The wastewater passes through a conveyor belt screen that removes plant influent and large debris.

- Clarifiers: The clarifiers slow the flow of water, allowing heavy particles to settle to the bottom of the tank. The solids or sludge are pumped to the sludge thickener and the digester (8) for further treatment.

- Biofilter: The biofilter continually distributes water over rocks that provide a home for microorganisms. The microorganisms break down dissolved organic material into simpler inorganic chemicals. The biofilter conditions mimic the environment of rocky streams and ocean coasts.

- Biotower: Bacteria living in the biotower convert ammonia in the water to a form of non-toxic nitrogen.

- Sandfilter: The sandfilters remove any remaining particles that might interfere with the next step: the ultraviolet (UV) disinfection.

- UV Disinfection: High intensity Ultra Violet light is used to inactivate any remaining bacteria to prevent spread of harmful diseases before final discharge into the marsh.

- Outlet to Marsh: The water discharges to the marsh, providing wildlife habitat. Since wastewater provides organic and inorganic nutrients, it contributes to the basic food chain of the marsh.

- Sludge Digestion: Sludge removed from the clarifiers is pumped into digesters where bacteria break down solids and produce methane gas. The methane gas is recovered to heat the digester.

- Sludge Processing: Solids from the digesters, which are now called biosolids, are dried in a centrifuge before being used as alternative daily cover at a landfill.